Before the CPUs Were Under Your Hood...

I ran across the article below in the September 1965 issue of Dodge News magazine, written by freelance automotive author Bob Rosekrans. The technology references are interesting. The article also sheds some light on assembly line procedures.

To put things in perspective, this was written about two and half years before the US Defense Advanced Research Projects Agency began funding work on ARPANET, what we today call the Internet. Prior to ARPANET packet switching, networking computers through serial interfaces was slow and complex compared to what we're used to today. Teletype (tty) machines were like networked electric typewriters -- think of the machine that would have printed codes on your broadcast sheet.

Compare those computers processing 5,000 instructions per second to a modern laptop processing over 3,000,000,000 instructions per second, or the 20,000-digit core memory to a laptop with over 2,000,000,000 bytes (2GB) of RAM.

And a 2,000,000 digit random access file system can't store a large picture from your camera phone. Modern 2TB hard drives have a capacity of roughly 2 trillion (2,000,000,000,000) bytes.

685

685

After a defect has been located by an inspector and recorded in the computer

And in the case of Chrysler Corporation it is a tool which in cooperation with Chrysler personnel will make your Dodge even more dependable for years ahead

And it broadcasts this defect information to the affected supervisor on the line and to the quality control team

And it is certainly true that they can do many jobs that our brains can do and do them faster and much more accurately

And I was

and to your driveway

-as long as it was black and four-door

As your car reaches the end of each section or department it must be

At a production rate of 60 cars per hour failure to detect a needed correction trend for an extended period can create a need for action on a large number of cars

At each of the

At the

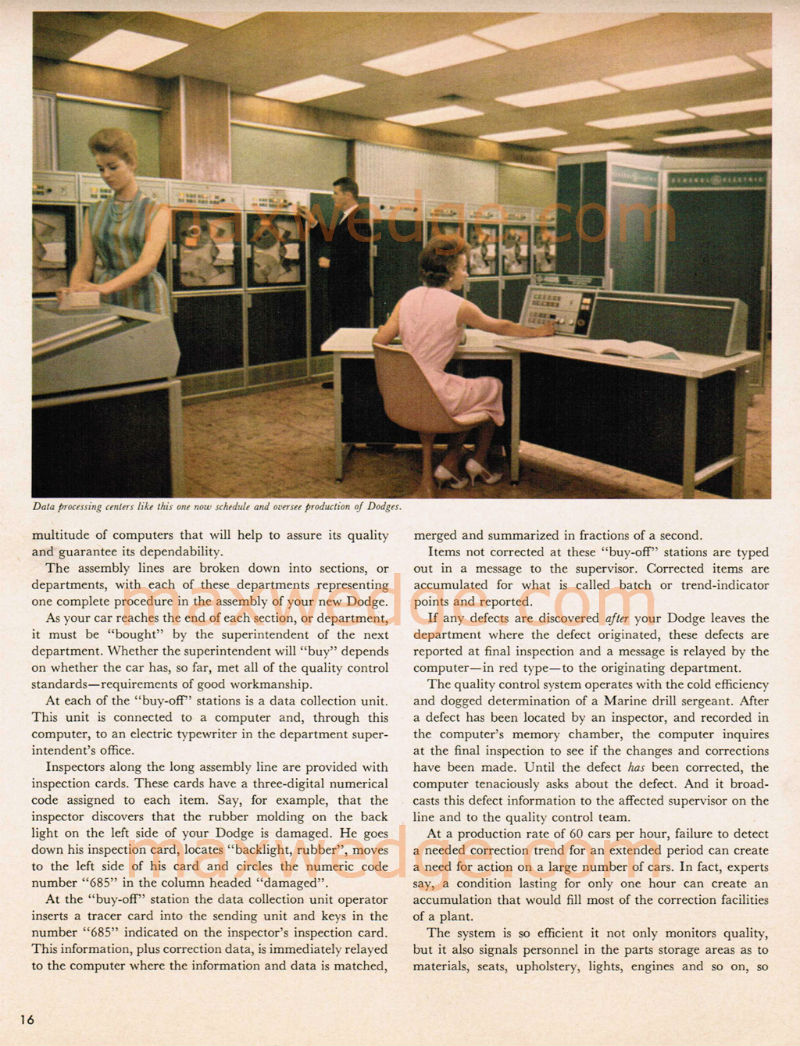

At the Dodge plant near Detroit for example there are seven separate quality reporting stations at each of its two assembly lines

At the plant your car is immediately given an identification number

At the time I had the temerity to order my car with a minor equipment change that deviated from the usual

backlight rubber

bought

But the computer is really only a sophisticated tool; a tool that needs man for its successful operation at maximum efficiency

buy

buy-off

buy-off

buy-off

By Bob Rosekrans

by the superintendent of the next department

Called officially the Dynamic Quality Control System the system of computers used by Chrysler Corporation can make logical decisions at the rate of 5000 per second

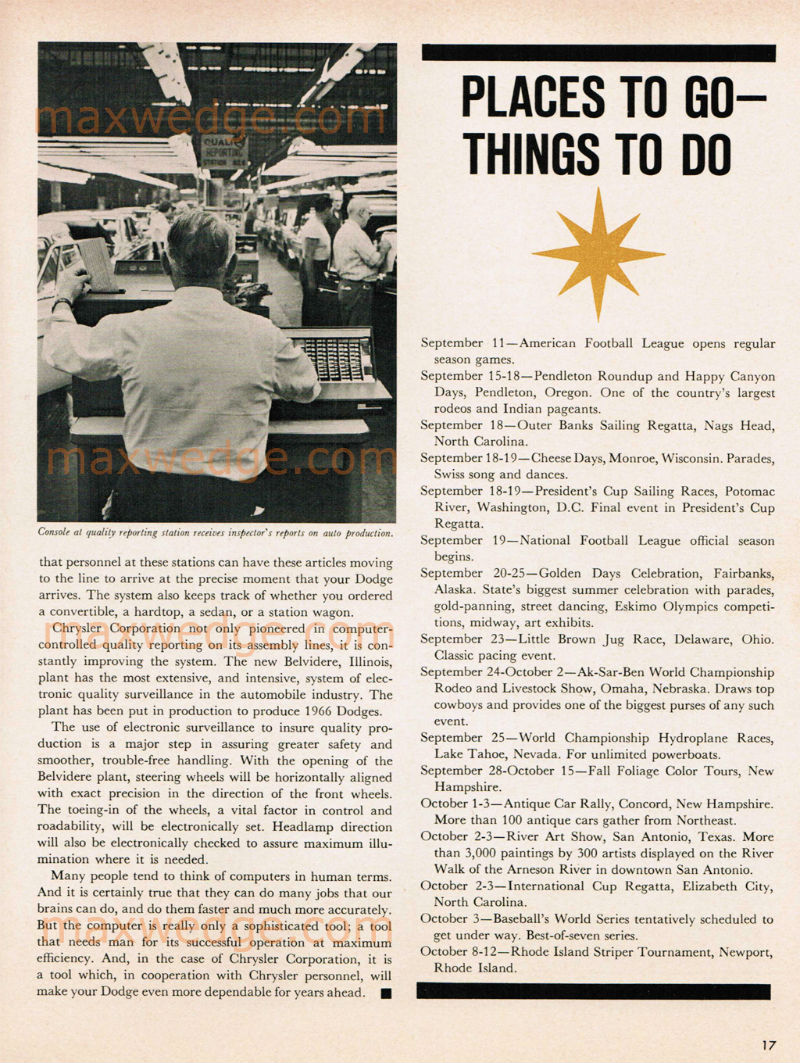

Chrysler Corporation not only pioneered in computer-controlled quality reporting on its assembly lines it is constantly improving the system

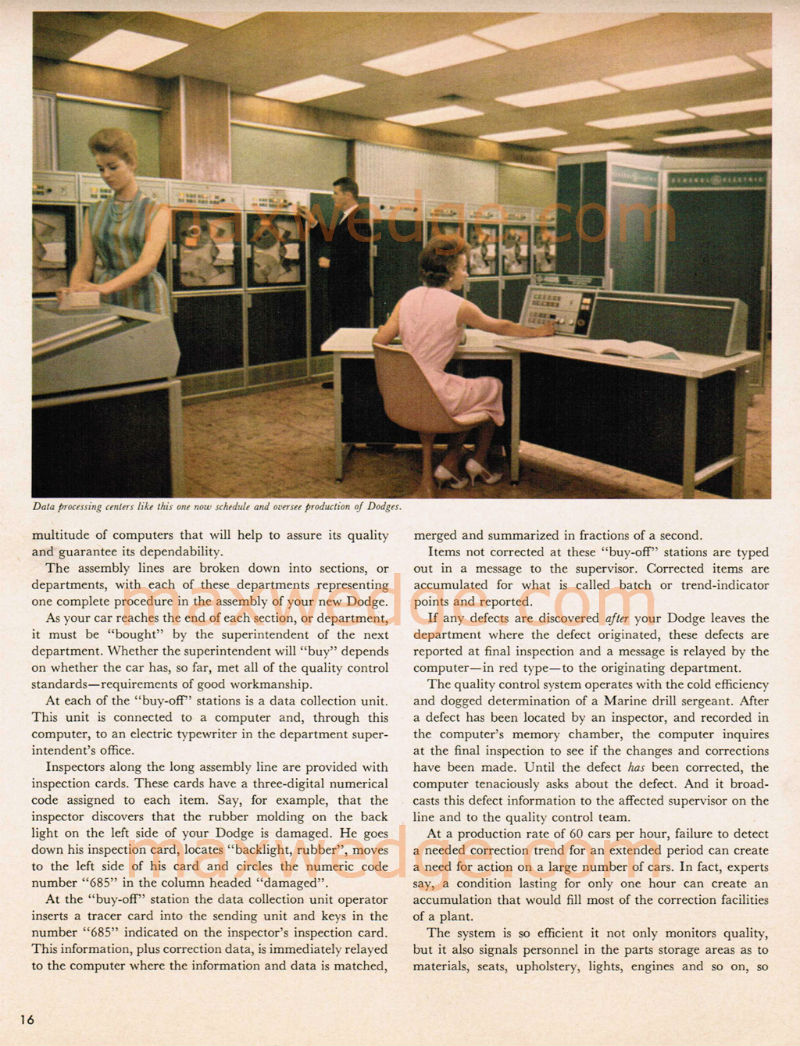

Computers are used extensively by Chrysler Corporation to insure quality production of a quality product

Corrected items are accumulated for what is called batch or trend-indicator points and reported

customer with a special taste for special equipment and accessories walked into his local Dodge dealership to buy a new Dodge Polara

damaged

d be sorry the salesman warned

depends on whether the car has so far met all of the quality control standards

Each day information is consolidated and sent to quality information processing centers

Even though this was a far cry from the days when you could have any car

feeder

First employees of the dealership who sold him the car translated the order into a numeric code that would be pure gibberish to most of us

For instance you can get a Dodge Coronet today in an unbelievable 6330000 possible combinations of parts and accessories; enough combinations to keep an average Detroit production line operating for 25 years without producing two identical cars Is it any wonder that forward-looking car makers like Chrysler Corporation have turned to the computer to speed car delivery to their customers

From then on his order for a new Polara went through an amazing process

From this moment your Dodge is in the capable brains of a multitude of computers that will help to assure its quality and guarantee its dependability

Headlamp direction will also be electronically checked to assure maximum illumination where it is needed

He goes down his inspection card locates

Here the order is edited to be sure that the customer has ordered acceptable combinations of equipment-

He was carrying a neatly typed sheet with a long list of optional equipment that he wanted on his car

I

If any defects are discovered after your Dodge leaves the department where the defect originated these defects are reported at final inspection and a message is relayed by the computer

If every man woman and child in the city of New York were to order a new Dodge Coronet every single car could be different

indicated on the inspector

In fact experts say a condition lasting for only one hour can create an accumulation that would fill most of the correction facilities of a plant

-in red type-

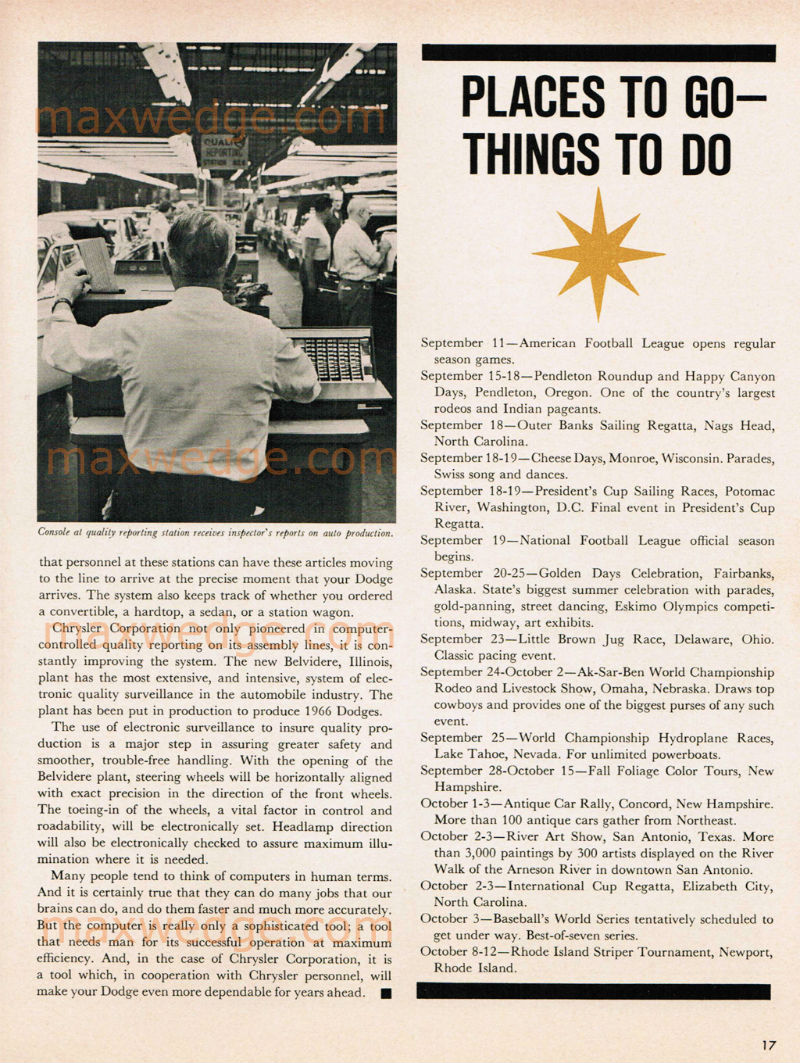

Inspectors along the long assembly line are provided with inspection cards

in the column headed

I remembered the first new car I ever bought

Items not corrected at these

It included among other things an auto-pilot and special rear axle ratios

-it was a long ways from the near perfection attained with the assistance of today

It was back in the days before World War II

I waited nearly four months for delivery of my car

Last month in a small town in upstate New York a

Let

lines

Listening to a computer expert explain the system is like listening to Einstein give a lecture on the theory of relativity in Latin

Many people tend to think of computers in human terms

moves to the left side of his card and circles the numeric code number

Not any more

Not only do computers assist in the scheduling and the assembly of your Dodge they also check it at every step for flaws in construction

-requirements of good workmanship

s 18 million decisions every hour

s assembly plant data processing centers

Say for example that the inspector discovers that the rubber molding on the back light on the left side of your Dodge is damaged

s computers can within 250 milliseconds have access to any of 2 million digits stored in random-access disk files

s follow your new Dodge from the moment that you sign the purchase order until it moves off the assembly line bound for your hometown

s inspection card

s list of optional equipment nodded and began to fill in an order form

s memory chamber the computer inquires at the final inspection to see if the changes and corrections have been made

s memory so a quality and reliability survey is constantly available

s nightmare

s office

Soon the customer had signed the purchase order and gone on his way

s space-age computers

stations are typed out in a message to the supervisor

stations is a data collection unit

station the data collection unit operator inserts a tracer card into the sending unit and keys in the number

Suppose we break this down to show you what it means to you

That

that trims and paint are compatible that the engine matches the transmission and axle

The assembly lines are broken down into sections or departments with each of these departments representing one complete procedure in the assembly of your new Dodge

The computers monitoring these lines have a memory capacity of 2 million characters

The Dodge salesman took the man

The new Belvidere Illinois plant has the most extensive and intensive system of electronic quality surveillance in the automobile industry

Then the order is fed into a computer which turns it into data to be matched against production schedules

The plant has been put in production to produce 1966 Dodges

The quality control system operates with the cold efficiency and dogged determination of a Marine drill sergeant

There was a time in the automobile industry when such orders were fraught with opportunities for confusion and delay

These cards have a three-digital numerical code assigned to each item

The system also keeps track of whether you ordered a convertible a hardtop a sedan or a station wagon

The system is so efficient it not only monitors quality but it also signals personnel in the parts storage areas as to materials seats upholstery lights engines and so on so that personnel at these stations can have these articles moving to the line to arrive at the precise moment that your Dodge arrives

The toeing-in of the wheels a vital factor in control and roadability will be electronically set

The use of electronic surveillance to insure quality production is a major step in assuring greater safety and smoother trouble-free handling

This coded information was sent to one of Chrysler Corporation

This information plus correction data is immediately relayed to the computer where the information and data is matched merged and summarized in fractions of a second

This number is stored in a computer

This unit is connected to a computer and through this computer to an electric typewriter in the department superintendent

to the originating department

To the people of Chrysler Corporation with a data communication system among the most advanced in the world the order was routine

Until the defect has been corrected the computer tenaciously asks about the defect

When availability of options and accessories had been checked personnel following a precise schedule controlled by other computers feed these parts on to

Whether the superintendent will

Will it fit the fixturing and tooling capacities Will all the right parts be on hand With the computer as an aid Chrysler personnel quickly answer such questions

With 20000 digit core memories one of Chrysler

Without computers to solve the production problems the making of automobiles in this variety could rapidly turn into a plant manager

With the opening of the Belvidere plant steering wheels will be horizontally aligned with exact precision in the direction of the front wheels